Flexible drinking straw bending machine is designed to transform straight drinking straws into flexible ones. This equipment is suitable for various straw types, including pp, PLA (Polylactic acid), and paper straws. The machine operates automatically, requiring minimal input from the operator, who only needs to load materials into the hopper. Straight straws are fed into the machine at the top, where they are individually inserted into the main drum and secured by mechanical catches.

Key Features:

– The forming components of the flexible drinking straw bending machine are made of durable alloy steel, ensuring long-term usage.

– Consistent production capacity.

– Automated product counting, preset quantity control, and user-friendly operation.

– Automatic shutdown in case of malfunctions, ensuring reliability.

| item | KDCY-4 | KDCY-5 | KDCY-6 |

| Driving Motor | 1.5Kw(Inverter Control) | 1.5Kw(Inverter Control) | 1.5Kw(Inverter Control) |

| Processing Speed | 200-300Pcs/min | 200-300Pcs/min | 200-300Pcs/min |

| Inside Diameter | 3.8mm | 4.8mm | 5.8mm |

| Length Of Straight Straw | 155∼245mm | 190∼260 mm | 190∼260 mm |

| Length of Flexible Straw | 140∼235 mm | 175∼245 mm | 175∼245 mm |

| Straw Wall Thickness | 0.2±0.02mm | 0.15±0.02mm | 0.15±0.02mm |

| Top Section Length | 30-50mm(Adjustable) | 30-50mm(Adjustable) | 30-50mm(Adjustable) |

| Length of flex. Part | 8-11mm(Adjustable) | 8-11mm(Adjustable) | 8-11mm(Adjustable) |

| Dimension | 1500x1800x1600mm | 1500x1800x1600mm | 1500x1800x1600mm |

| Weight | 1.0t | 1.0t | 1.0t |

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

PP drinking straw machines warehouse

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

Loading Drinking Straw Machine Warehouse into container

Our Main parts cooperator as following brand,but standard parts all made from China.

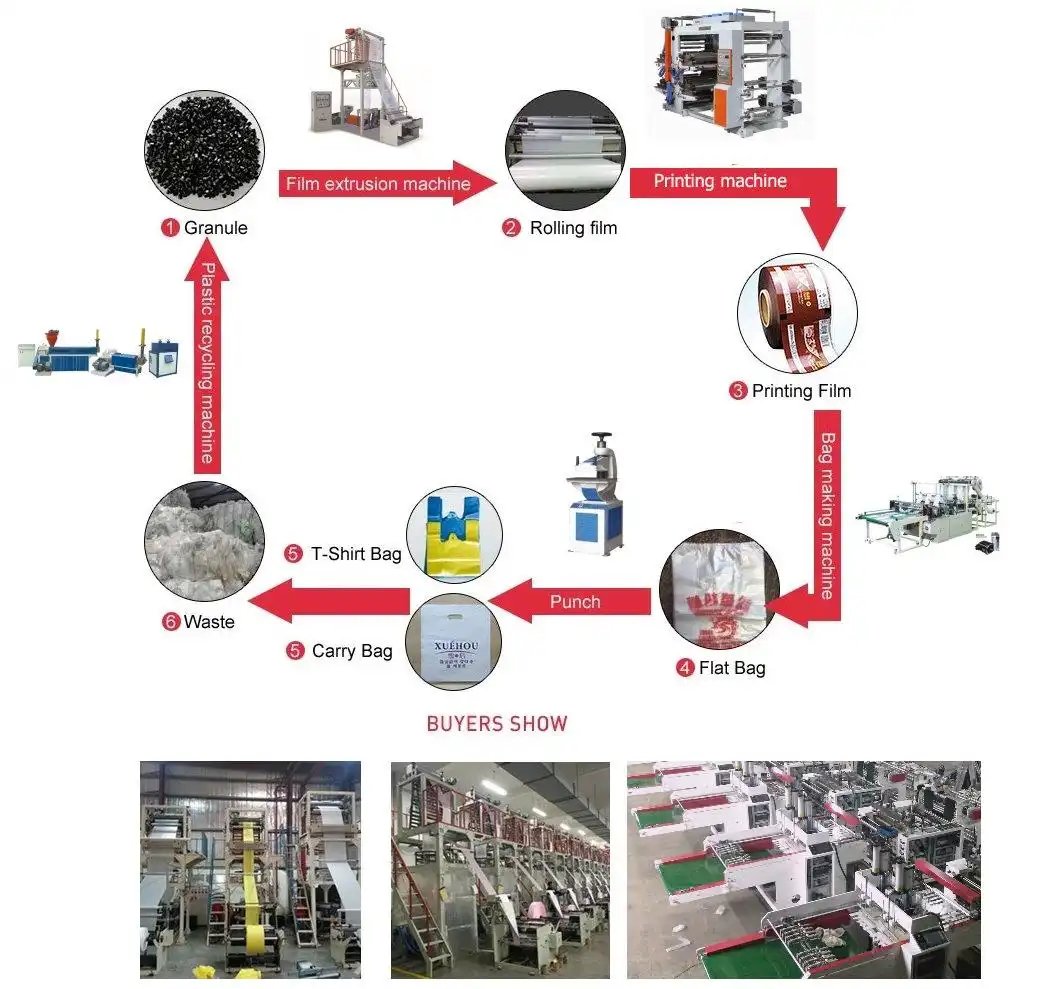

How To Find Polyethelene For Blown Film Extrusion.

Extrusion Film Extrusion use Polyethelene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company

Kingdom Machinery Co., Ltd. is a manufacturer and supplier of plastic film and plastic bag production equipment for the entire factory, including blown film machines, bag making machines, flexible printing machines, copper tube machines, recycling extruders, stretching film machines, and foaming machines.